how to use a water jet cutter

The smaller orifice the smaller the cut width kerf. The concept of waterjet is quite simple.

This process is ideal for soft and medium-hard materials.

. The first small waterjet cutter in a compact package. A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water or a mixture of water. Using Water Jet Cutting on Cams.

A water jet cutter is a device capable of cutting right into metal or other materials utilizing a jet of water at high speed rate and pressure. Tips for Your DIY Water Jet Cutter. A water jet cutter is a commercial tool that cuts various materials using a high-pressure water jet or a mixture of water and an abrasive substance.

What is Water Jet Cutter. Once the CAD rendering is loaded the water jet. The diameter of the orifice helps determine the cut width kerf.

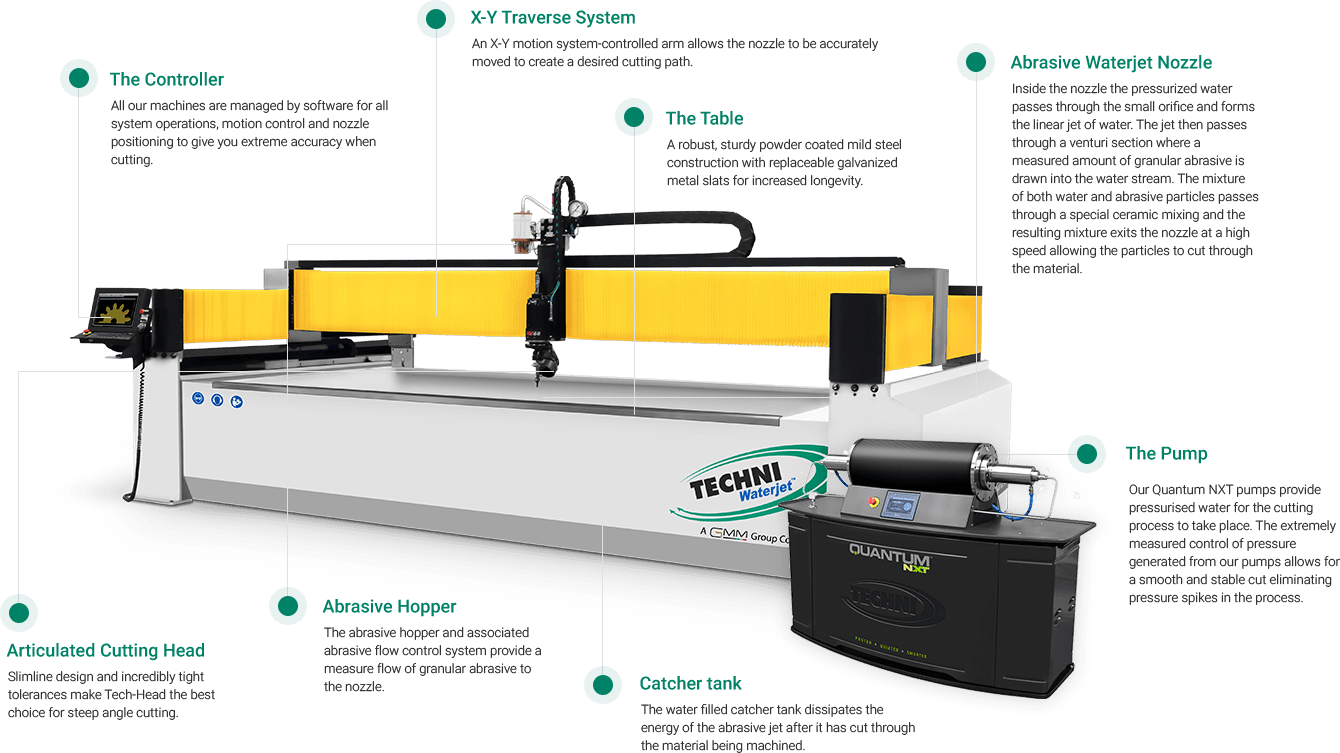

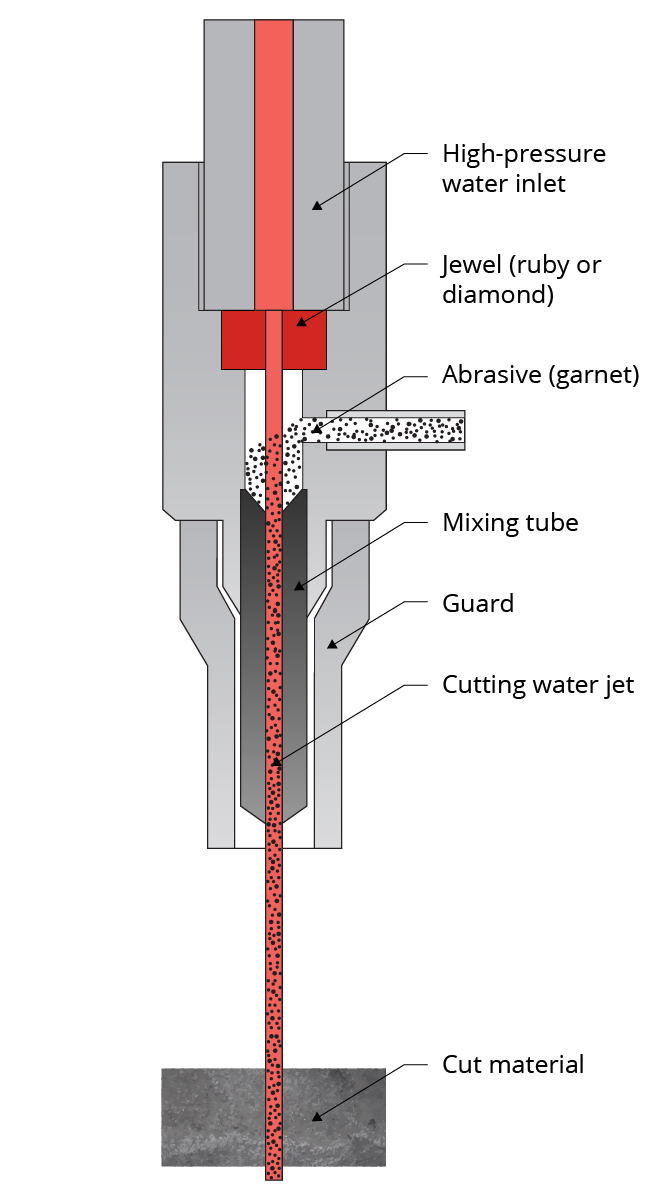

Using a ruby or diamond jewel the orifice focuses the high-pressure water. Waterjet cutting begins by using the nozzle to clean away any excess material that could interfere with the cutting process. Startup machine using the appropriate start up process.

After all leversswitches have been turned on in proper order then hit the reset button on the machinepump grey button b. In some cases the water is supplemented with. The first pure waterjet cutting uses a.

Water cutters operate by pushing water out of a cutting head at extremely high speeds. Cams can easily be made using water jet cutting. Water at this pressure can penetrate into firm materials.

I was getting a lot of questions about how the Flow Mach 500 waterjet works so I decided to answer all of them with this video. Pull up cutting head Flip up protective yellow cup Remove part and workpiece Lower the water lockline Spray down the aluminum surface Clean garnet trays see next slide Leave the water. It is best to use underwater cutting to reduce the noise generated when cutting aluminum.

I show the basics of what a w. Like most cutting methods a water jet cutter can be noisy. Pure waterjet cutting uses pure water to complete the operation.

Aug 11 2021 Bokep Indo Skandal Baru 2021 Lagi Viral - Nonton Bokep hanya Itubokepshop Bokep Indo Skandal Baru 2021 Lagi Viral Situs nonton film bokep terbaru dan terlengkap 2020. Waterjet cutting is simply an accelerated erosion process within a selected material. Using Water Jet Cutting on Cams.

Yet its still industrial grade enough to CNC cut steel. All that needs to be determined is the desired shape. After this has been done its time to create the cut.

Using waterjet cutters is the ideal option for cutting cement boards metals fiberglass and other materials used in construction work. This machine is considered the most environmentally friendly.

How Waterjet Technology Works Flow Waterjet

Water Jet Cutting Through 3 Inch Thick Aluminum Metal 4 X 6 Youtube

5 Fast Facts About Water Jet Cutting Cutting Onemonroe

What Is Waterjet Cutting Technology And How Does It Work Techni Waterjet

Turning A Waterjet Cutter Into A Wood Lathe For No Reason Hackaday

Sustainability And Waterjet Cutter Woodguide Org

Laser Cutter Vs Water Jet Cutter Stylecnc

Preparing A Fabricator S Game Plan For Jumping Into Waterjet Cutting

Water Jet Cutting Cost Effective Contract Cutting

What Is A Waterjet Cutting Machine

Abrasive Waterjet Cutting Machine Waterjet Cutters Equipment

Basics Of Waterjet Cutting Same Waterjet

Waterjet Cutting In Sacramento Ca Microform Precision

The Design And Development Of The First Ever Low Cost Waterjet Cutter Youtube

7 Benefits Of Precision Waterjet Cutting

Small Cnc Mini Low Cost Water Jet Cutter From China Manufacturer Headwaterjet